Choosing the right Polyester Printing Mesh can be a daunting task for many businesses. The quality of printing largely depends on the mesh type selected. In 2022, the global demand for screen printing meshes reached over $1 billion. Polyester meshes accounted for approximately 65% of this market, evidencing their importance.

When considering options, evaluate the mesh count and thread diameter. A mesh count of 110 might be suitable for standard graphics. However, finer prints may require a mesh count of 280 or higher. This choice can impact ink transfer and resolution. Incorrect choices can lead to disappointing results.

Understanding your printing needs is vital. Some businesses overlook the importance of testing various mesh types. This could lead to inconsistencies in print quality. Researching and consulting experts can prevent costly mistakes in the long run. Ultimately, selecting the ideal Polyester Printing Mesh may require time and effort, but it significantly enhances the final product.

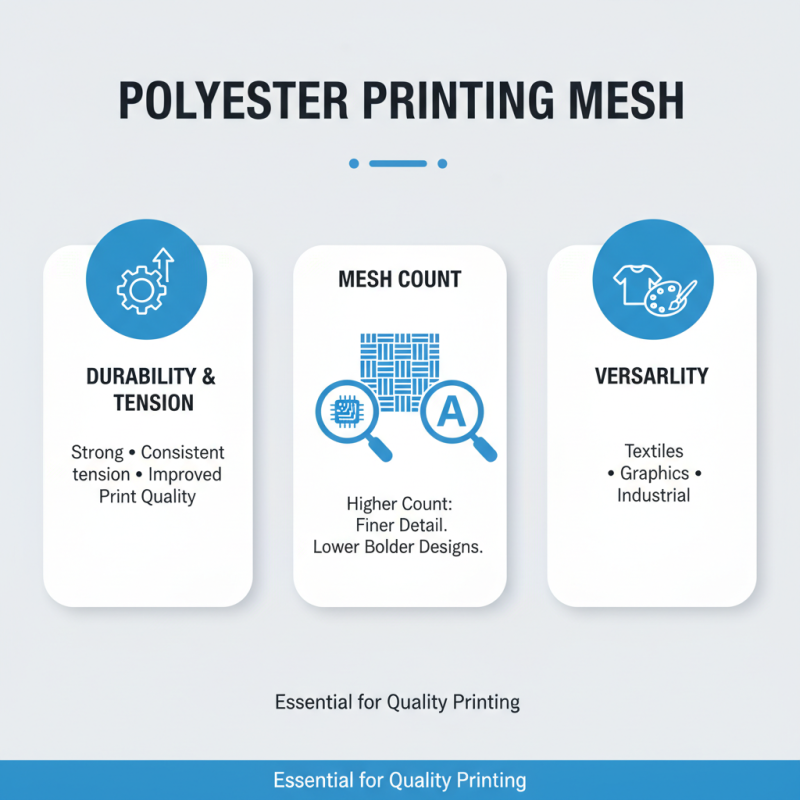

Polyester printing mesh is widely used in various industries, from textiles to graphics. Understanding the mesh's properties is essential. Polyester mesh offers durability and excellent tension. This improves print quality significantly. The mesh count affects the level of detail you can achieve. Higher counts yield finer detail, while lower counts allow for bolder designs.

Applications vary greatly. For screen printing, choosing the right mesh is crucial. It influences how the ink passes through. Choosing too fine a mesh may lead to clogged screens. Alternatively, a mesh that's too coarse may not capture the design accurately. Testing is often required to find the perfect balance. This trial-and-error method can feel time-consuming, but it enhances the final output.

It's also important to consider the fabric type. Different materials react differently to inks and textures. For example, polyester blends may require specific mesh choices. Reflecting on these factors can prevent costly mistakes. Ensuring compatibility will save time and effort. Remember, the goal is to achieve clarity and precision in every print.

Choosing the right mesh count for polyester printing is crucial.

It impacts both print quality and production efficiency.

Standard mesh counts vary from 40 to 300 threads per inch (TPI).

Each count serves distinct purposes.

For example, lower counts like 40-110 TPI are ideal for high-viscosity inks and thicker designs.

In contrast, higher counts can produce finer details and sharper images, making them suitable for delicate artwork.

When assessing mesh counts, consider the ink type and substrate.

A report from the Screen Printing and Graphic Imaging Association states that using a 200 TPI mesh can increase ink savings by up to 30%.

However, precision comes with challenges.

Higher mesh counts may lead to clogging, affecting production speed.

It’s vital to balance detail with practical output.

Remember, experimenting is essential.

Adjustments might be necessary to find the right fit.

Some printers skip testing and face inconsistent results later.

Regular evaluation of your mesh count is necessary for quality assurance.

This helps in maintaining smooth operations and achieving the best prints.

Understanding these factors will guide you in making informed choices for your polyester printing needs.

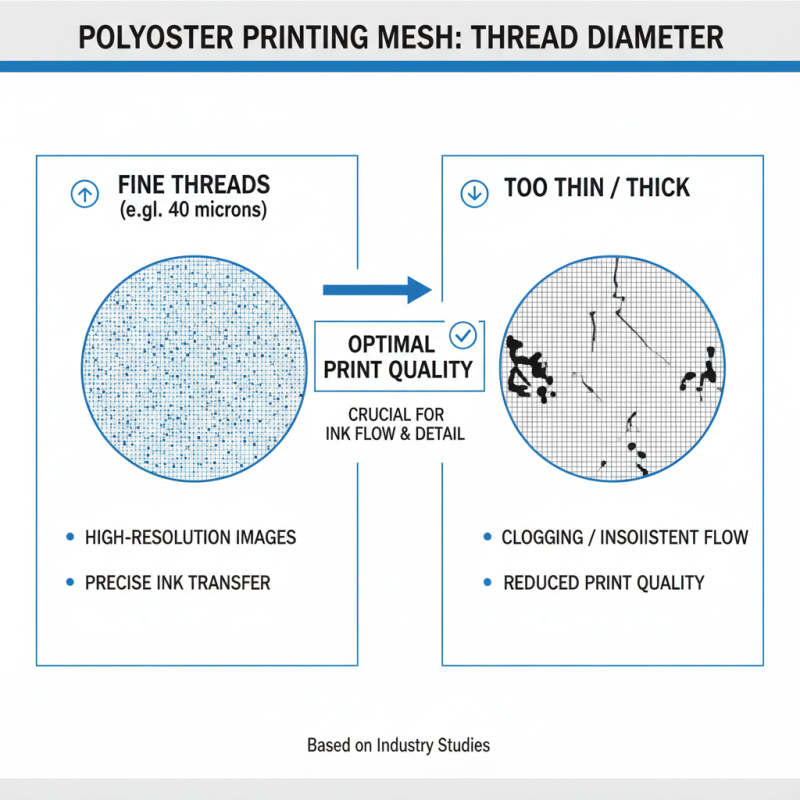

Choosing the appropriate thread diameter in polyester printing mesh plays a crucial role in print quality and ink flow. According to industry studies, finer threads often enhance details. A thread diameter of 40 microns is common for high-resolution images, allowing for precise ink transfer. However, using a diameter too thin may lead to issues like clogging and inconsistent ink flow.

Larger thread diameters, such as 90 microns, provide better ink and adhesive flow. They are more suitable for thicker inks and larger designs. This can prevent build-up and allow for smoother printing with vibrant colors. Yet, one must consider that larger threads can result in less detailed prints. Finding a balance is essential.

In practice, many printers face challenges in this area. Some may choose a finer mesh out of habit, only to struggle with ink adherence. Others opt for broader threads without recognizing the potential loss of detail. Adjusting thread diameter based on specific projects can elevate print outcomes significantly.

When choosing between monofilament and multifilament polyester mesh, consider their distinct characteristics. Monofilament mesh is made from a single strand of polyester. This design often results in greater durability. Reports show that they offer a tighter weave, enhancing print quality. They can withstand higher tension during printing processes as well, making them suitable for detailed work.

On the other hand, multifilament mesh consists of multiple strands twisted together. This type is known for its flexibility and softness. Some argue these qualities allow for smoother handling and less damage to delicate substrates. However, the tighter construction of monofilament often produces sharper images. Data indicates that approximately 65% of print professionals prefer using monofilament for high-precision jobs. Yet, many find multifilament preferable for softer applications.

Still, errors can occur when selecting mesh types. In practice, some printers mistakenly underestimate the importance of mesh choice. This can lead to compromised print quality. A mesh’s threading and weave density can significantly affect ink flow and drying times. Choosing the right type requires careful consideration of the specific job at hand. Balancing durability and flexibility needs is crucial, and getting it wrong can affect the finished product.

| Mesh Type | Filament Count | Mesh Opening (microns) | Tension (N/cm) | Best Uses |

|---|---|---|---|---|

| Monofilament | 43 | 34 | 25 | High precision printing, fine detail |

| Monofilament | 55 | 25 | 35 | Textile printing, durable applications |

| Multifilament | 40 | 40 | 20 | General screen printing, thicker applications |

| Multifilament | 60 | 30 | 30 | High-volume production, robust designs |

When selecting a polyester printing mesh, understanding coatings and surface treatments is crucial. These elements greatly influence durability. A well-coated mesh withstands harsh environments. For example, a special coating can resist chemicals. This means fewer replacements over time. However, some coatings may not adhere well in humid conditions, leading to unexpected issues.

Surface treatments also play a significant role. They can enhance ink adhesion. A smoother surface might seem ideal, yet it can lead to ink bleed if not matched correctly. On the other hand, a textured finish can improve print quality. But it may wear down faster under certain pressures.

Reflecting on your choices is essential. Not every coating will suit every project. A durable mesh often requires careful matching of coating and task. Be aware that conditions change. A treatment effective today might fail tomorrow in different settings. Always consider the long-term implications of your choices. Test them thoroughly if possible.