In the world of textile printing, "Polyester Printing Mesh" stands out for its versatility and durability. John Duncan, a renowned expert in the field, once said, "The right mesh can transform an ordinary print into something extraordinary." This statement resonates in many projects requiring precision and clarity.

Choosing the best polyester printing mesh requires understanding various options. From thickness to weave density, these factors influence the final product's quality. The mesh you select can affect ink distribution and color vibrancy. This decision can make or break your project.

Mistakes commonly happen during selection. Not every mesh suits every design. Some might choose based solely on price. This often leads to unsatisfactory results. Reflecting on past projects is essential. Learning from errors can guide future choices in polyester printing mesh. The right materials are crucial for achieving artistic visions.

When selecting polyester printing mesh for various projects, understanding the options is crucial. Polyester mesh fabrics are versatile and offer excellent durability. These materials are widely used in signage, screen printing, and various industrial applications. Reports indicate that the global market for printed textiles is expected to grow at a CAGR of 5.7% from 2021 to 2028. This growth reflects the rising demand for high-quality printing options.

Polyester mesh is praised for its lightweight properties and strength. Different mesh sizes are available. A finer mesh allows for detailed designs, while coarser options can offer durability. Data shows that finer mesh can achieve print resolutions of over 300 DPI. However, some users find that overly finer options can clog easily, requiring more maintenance and cleaning. Striking the right balance is essential.

Quality matters. Not all polyester meshes are created equal. A study showed that 30% of users reported dissatisfaction with the clarity of prints on lower-quality materials. It can be tempting to choose cheaper alternatives, but the investment in high-quality mesh pays off in the long run. Color fidelity and longevity of prints are essential factors for overall project success. Choosing wisely ensures better results.

Polyester printing mesh is versatile and widely used in various projects. It is a synthetic fabric made from polyester fibers. This material offers durability, flexibility, and ease of use. Artists and designers often prefer it for screen printing. The fine mesh allows for intricate designs and detailed artwork. It is perfect for both large runs and one-off prints.

In real-world applications, polyester mesh works in various settings. For instance, it’s used in sports jerseys, banners, and signage. The mesh provides breathability and durability, making it suitable for outdoor use. However, not every type of mesh is ideal for every project. Choosing the right mesh can be challenging. It requires understanding your specific needs and project requirements.

Consider the thread count and weave of the mesh. A tighter weave allows for finer details but can limit ink flow. A coarser mesh allows more ink but sacrifices detail. Experimenting with different options can lead to unexpected results. Mistakes in mesh selection can impact the final output quality. A hands-on approach is essential to finding the perfect fit for each project.

When choosing polyester printing mesh, several key factors come into play. The mesh count is crucial. A higher mesh count offers finer detail in prints. A lower mesh count allows for bolder layers of ink. For instance, screens with a mesh count of 200 are ideal for intricate designs. In contrast, a count of 40 is better for thicker applications.

Fabric thickness matters too. Thinner meshes can produce vibrant colors but may lack opacity. Conversely, thicker meshes can offer more durability but may not render fine details. The balance here is essential. According to industry reports, nearly 70% of printing professionals prefer finding this balance to optimize print quality.

Another significant factor is the type of polyester used. Different blends can affect durability and print quality. Not all polyester meshes are created equal. Some may stretch over time, leading to inconsistencies in future prints. Longevity is always a concern. Many users have reported issues with fading, especially in outdoor conditions. It’s an area that requires careful consideration.

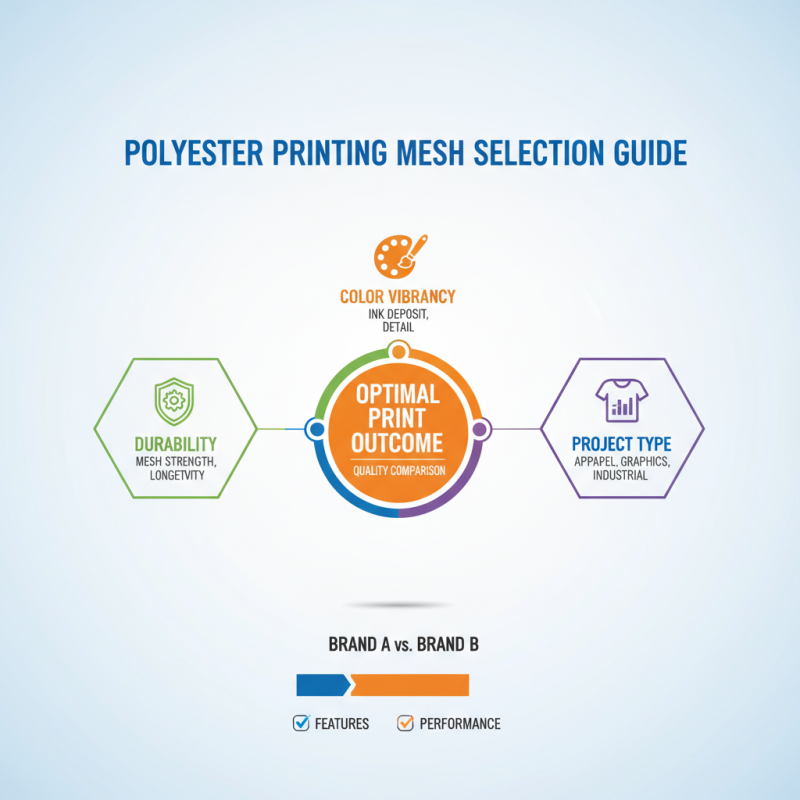

When selecting polyester printing mesh, it’s crucial to compare various options. The quality of the mesh can affect the final print outcome significantly. Different brands offer unique features. Some may excel in durability, while others stand out for color vibrancy. Understanding the purpose of your project can guide your choice.

One aspect to consider is the thread count. Higher counts generally mean tighter weaves. However, this is not always better for every application. Lower thread counts can yield softer prints, which may be desirable for certain designs. Additionally, think about the mesh's opacity. Some projects benefit from a more translucent option. Each choice leads to different results, and reflection on these differences is key.

Another factor is ease of use. Some meshes are more forgiving for beginners. Others might require advanced skills for optimal results. It’s important to assess your own experience level and project needs. Don’t overlook the importance of testing samples if possible. Experimenting can reveal unexpected preferences and insights. Ultimately, the best choice will depend on your specific goals.

Caring for polyester printing mesh is essential to maintain its quality. Proper cleaning can significantly extend the lifespan of these materials. It's important to avoid harsh detergents that can degrade the fibers. Instead, opt for mild soaps and lukewarm water. Using a soft brush can help remove stubborn dirt. Rinse thoroughly to ensure no soap residue remains.

Drying polyester mesh requires caution. Avoid direct sunlight, as it can cause colors to fade. Air drying is often best, but if you must use a dryer, select a low heat setting. Remember that high heat can damage the mesh. Regular inspections for wear and tear are important. Even small frays can lead to more extensive damage later.

Storing polyester printing mesh correctly is also vital. Keep it in a cool, dry place to prevent mold and mildew. Folding or rolling can create creases, which may affect printing quality. Using breathable storage bags can protect the material. Continuous use without care might lead you to regret poor maintenance choices. Realizing this sooner can save you time and money in the long run.

Polyester Printing Mesh is a versatile material widely used in various industries for screen printing and other applications. This article explores the top 10 options available, providing insights into their unique features and suitability for different projects. By understanding the properties of polyester printing mesh, users can make informed decisions based on their specific needs, whether for textiles, graphics, or industrial applications.

Furthermore, key factors such as mesh count, thread thickness, and fabric tension are crucial when choosing the right polyester printing mesh. The comparative analysis highlights popular brands, while maintenance and care tips ensure longevity and optimal performance of these products. Innovative uses across diverse industries demonstrate the adaptability of polyester printing mesh, making it an essential component for many creative and practical endeavors.